Latest and Greatest News

Why We Use 3D Printing (And Why It’s Not the Cheap Option Many Assume)

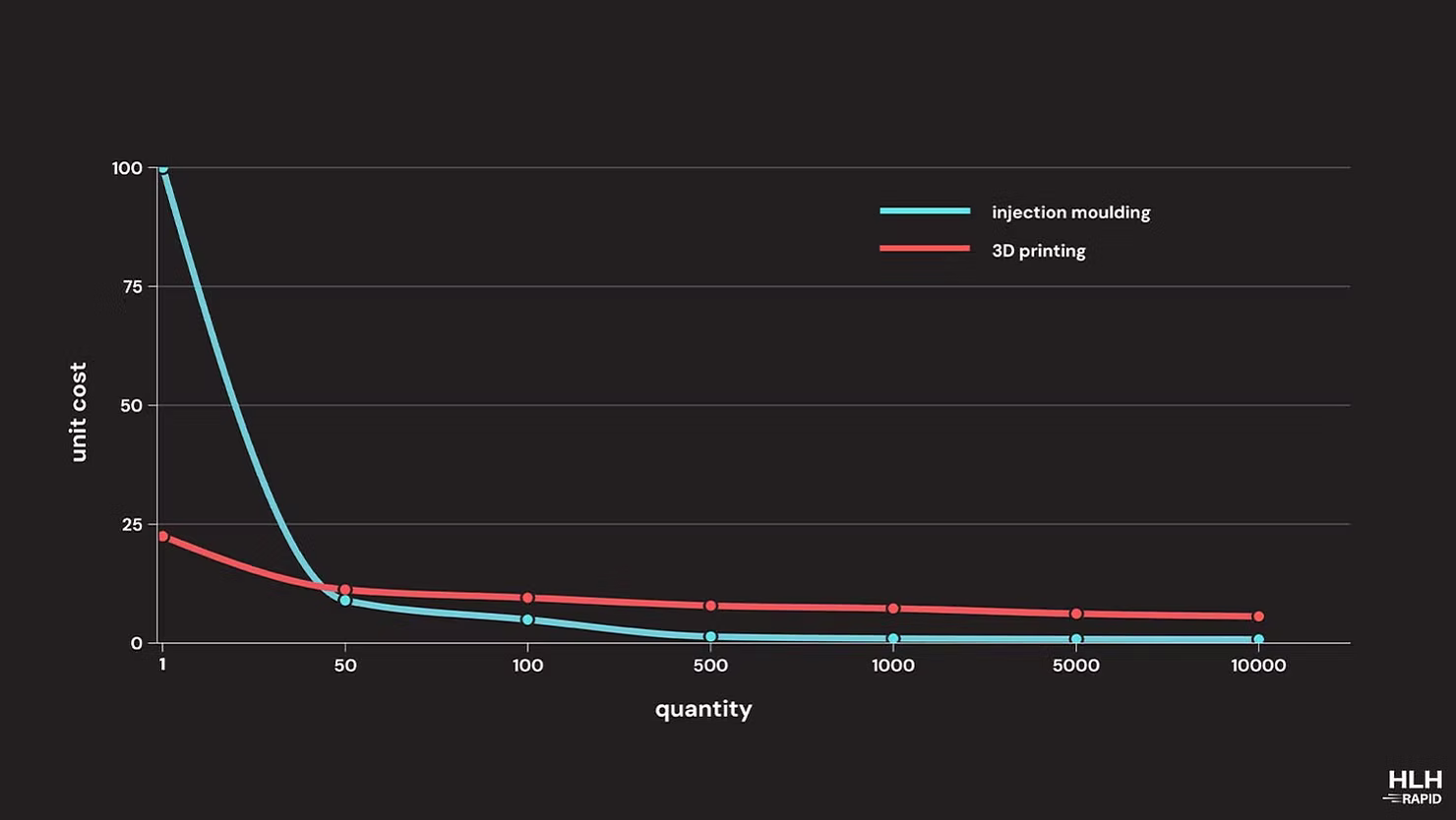

When people hear about 3D printing, they often assume it’s a cheaper alternative to traditional manufacturing methods like injection molding. That’s a common misconception. In reality, 3D printing is often more expensive per part than injection molding, especially when producing...

Reflecting on 2024: A Year of Growth, Innovation, and Community at Perry Parts

As 2024 fades in the rearview, we’re taking a moment to celebrate the milestones we achieved together. Perry Parts is built on a passion for innovation, specializing in 3D-printed, engineered products designed to thrive in some of the harshest conditions...

How Perry Parts Optimizes Stiffness with Density Modulation

To see the video version of this blog post: https://www.instagram.com/reel/DCXVawuSRhp/?utm_source=ig_web_copy_link&igsh=MzRlODBiNWFlZA==

Putting a 9.5" rear axle in a GX470

When we tackled Cruisers On The Rocks, we ended up destroying yet another 8-inch rear differential. This was the fourth one. If you do any serious off-roading with the GX 470 platform, you'll quickly notice the weakness of the 8-inch...

What an incredible weekend! I just got back from Cruisers on the Rocks, a premiere event for 100 and 200 series Land Cruisers held at Windrock Park in Tennessee.This was Perry Part's first time attending an event, and it was...

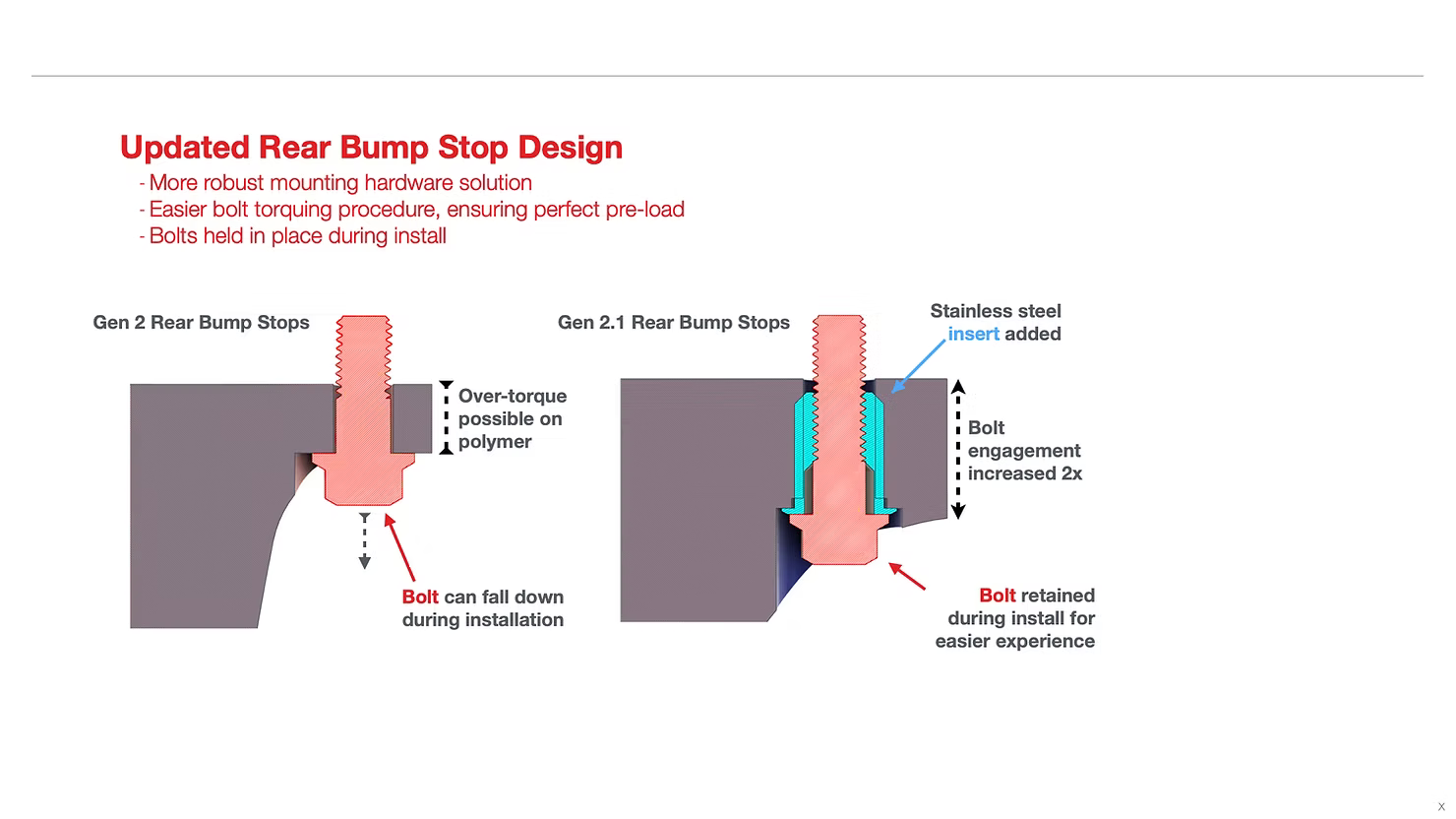

One of the most valuable things for us at Perry Parts is customer feedback. It’s how we improve and refine our products and make genuine strides in performance, durability, and accessibility for this hobby. Since launching the second generation...

Hydro Silencers - Silence your Hydro Bumps

Add Silence to the Smash: Introducing the Hydro Silencer for Hydro Bumps Want to watch the announce video? Check it out here: https://www.instagram.com/reel/DIMCusjRDJX/?utm_source=ig_web_copy_link&igsh=MzRlODBiNWFlZA== Hydro Bumps changed the game by transforming harsh bottom-outs into smooth, controlled compression. They're the best bump...

When we launched our Gen 2 product, we knew it was an upgrade, but after extensive time on the dyno studying its response and behavior, and running rigorous longevity tests, we can confidently say it’s a substantial improvement. It’s more...

When we started this business, it was truly an adventure into the unknown. While I have an engineering background in 3D printing, applying 3D-printed parts in such high-stress and high-strain applications was an entirely new challenge. Cross section comparison between...