Our Core Technology

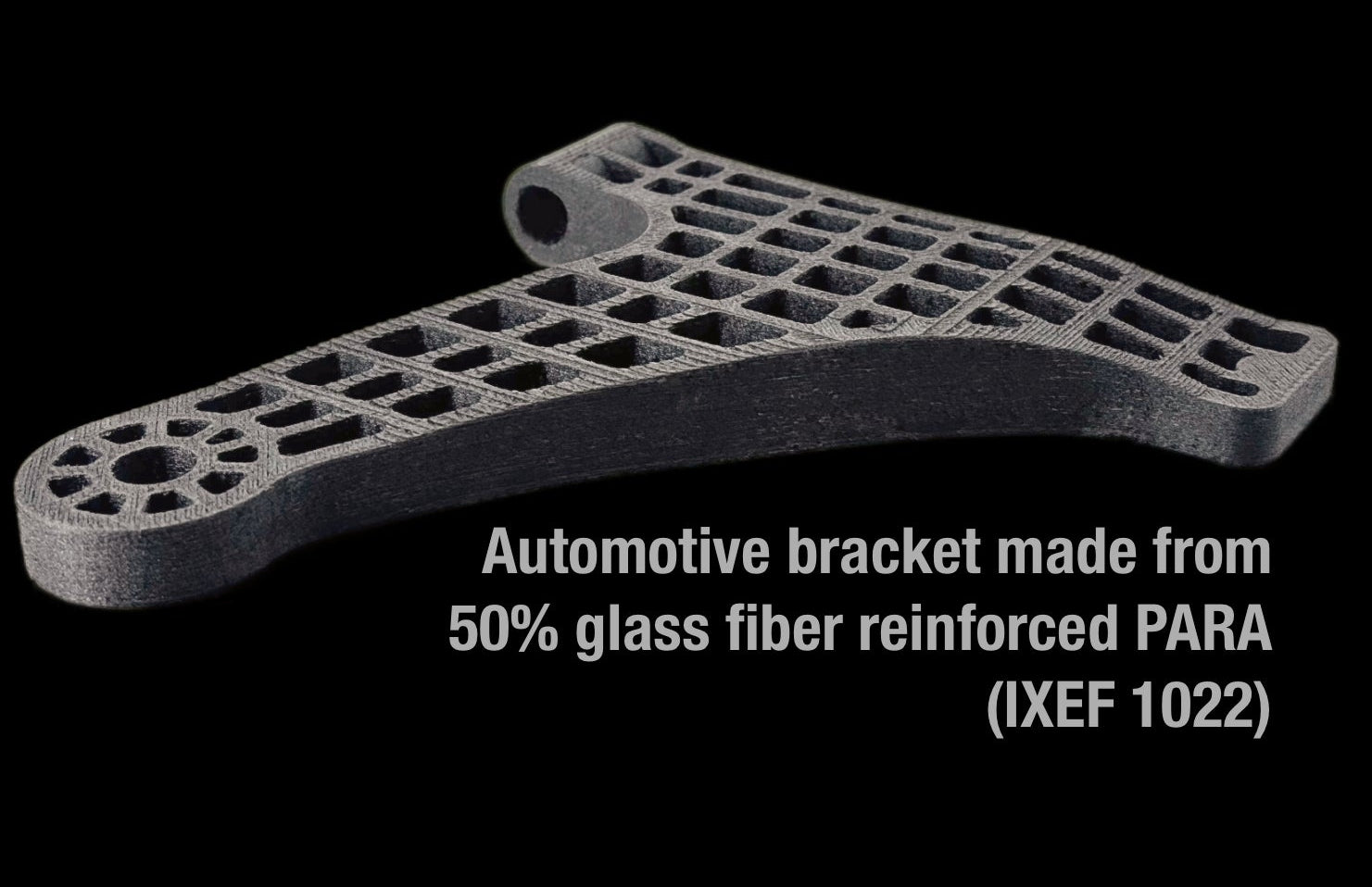

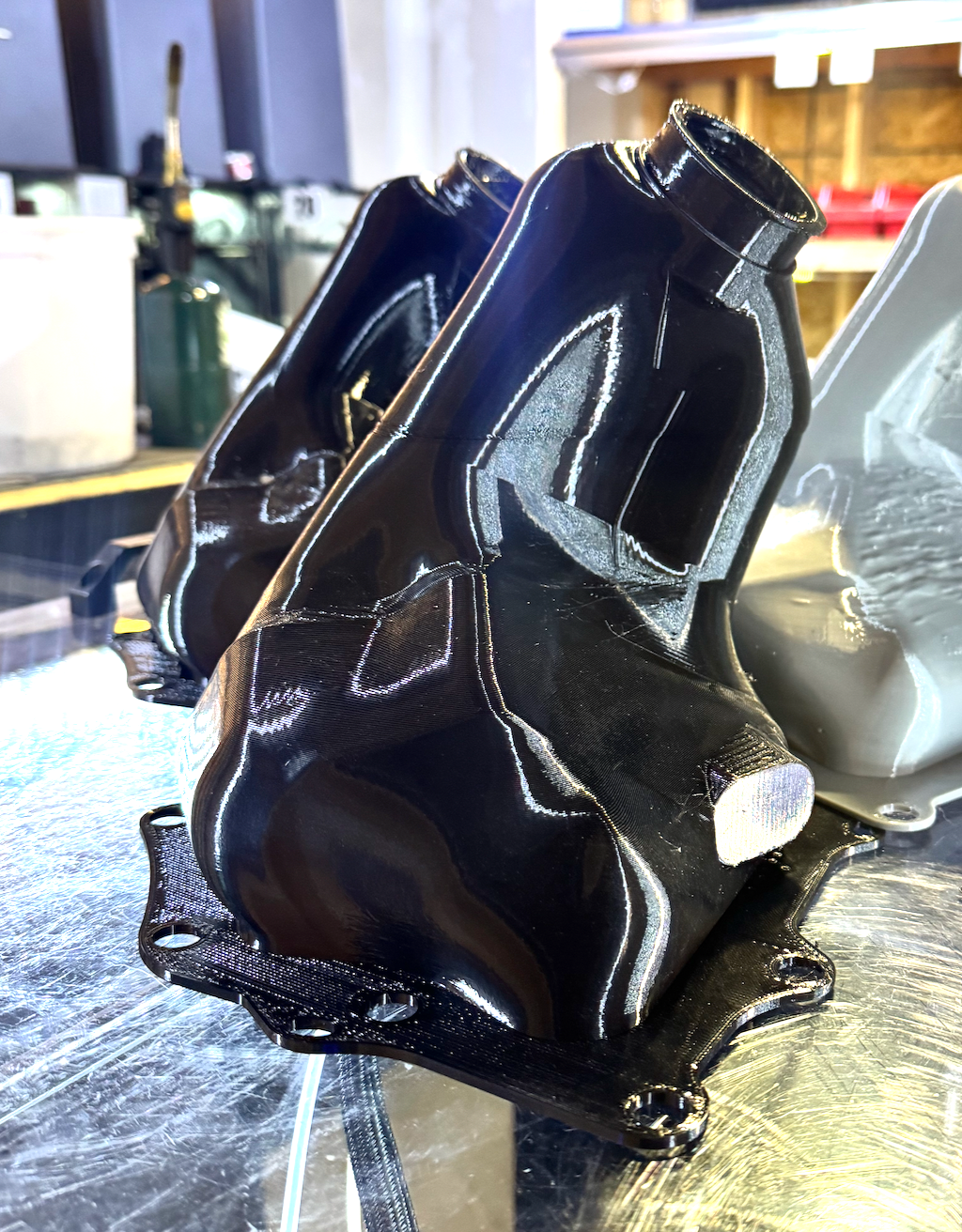

Building from industrial grade polymers without using filament or molds

We design, machine, and build our own purpose built pellet extrusion print heads, entirely in house. Using this technology, we can 3D print directly from the majority of molding grade polymers enabling unmatched part strength and design flexibility. We call this process Fused Granular Fabrication.

We have worked with

Combining the best of injection molding with 3D printing

STRENGTH

IF YOU CAN MOLD IT, WE CAN PRINT IT.

- We directly 3D print from industrial grade polymer granules, rather than filament.

- Our process reduces melt cycles by as much as 3x, improving strength

- Super rigid, high fiber reinforced (60%+) grades can be printed

- Ultra flexible materials down to Shore 40a can be printed

SPEED

BE THE FIRST AND MOST REFINED TO MARKET

- Iterate faster, with unmatched CAD to part timelines

- Spend no CAPEX on design changes

- Test multiple iterations simultaneously

SPECIALIZATION

CUSTOM, COMPLICATED DESIGNS ARE NO ISSUE.

- Build geometries that can't otherwise be manufactured

- Unmatched material selection

- Validate intricate structures, for tailored response.

SCALE

OVER 1000KG/MONTH PRODUCTION CAP AND GROWING.

- Perry Parts is the largest pellet extrusion manufacturer in the world.

- Leverage our unique skillset to bring your business and product to the next level